SUSTAINABILITY:

SARE Post Tensioning System offers multiple sustainability benefits for concrete structures:

1. Reduced material usage: Less concrete and steel are required, lowering embodied carbon and resource consumption.

2. Increased durability: Longer lifespan and less maintenance compared to conventionally reinforced structures, reducing environmental impact.

3. Energy efficiency: Thinner, lighter structures require less energy for heating and cooling, lowering energy consumption and carbon emissions.

4. Reduced waste: Efficient and optimized structural designs minimize waste during construction.

5. Reduced transportation emissions: Lighter materials decrease transportation emissions during delivery to construction sites.

Choose SARE Post Tensioning System for sustainable construction, achieving reduced material usage, increased durability, energy efficiency, waste reduction, and lower transportation emissions. Contribute to a more sustainable built environment with our post-tensioning techniques.

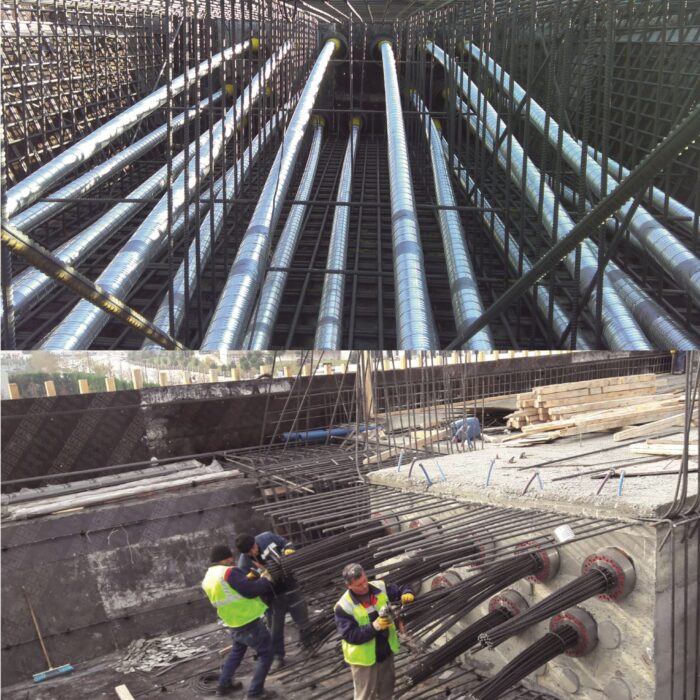

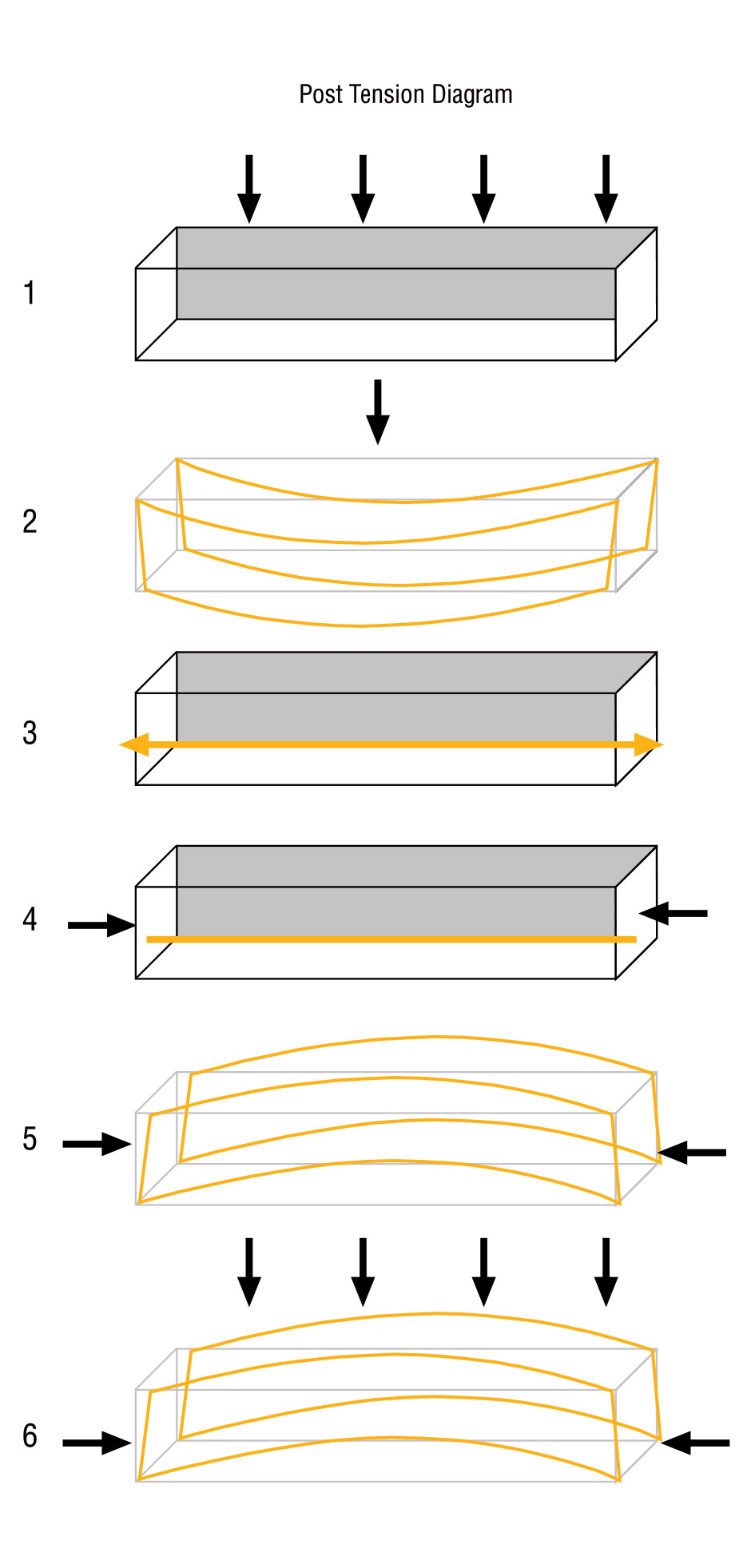

How Is The Post-Tensioning Application Made?

What Are The Advantages of Post-Tensioning System?

Structures built using post-tensioning systems have shorter production times compared to other methods. They offer larger spans in bridges, buildings, hotels, storages, silos, and similar structures. With reduced concrete and reinforcement, these structures become lighter, more economical, and more efficient. Additionally, the weight reduction positively impacts the seismic behavior of the structure. Experience faster construction, increased cost-effectiveness, and improved seismic performance with post-tensioning applications.

In What Type Of Structures Can Post-Tensioning Be Applied?

Post-tensioning is applicable in various large-scale structures, including bridges, high-rise buildings, hotels, silos, industrial storehouses, working areas, pools, water tanks, chemical storage tanks, and any structure requiring impermeability. Enjoy the benefits of post-tensioning technology in diverse construction projects where durability and water-tightness are paramount.

What is Post-Tensioning?

It is a special production process designed for increasing the tensile load capacity of the concrete. The desired compressive force in the concrete is obtained by stretching the high-strength steel strands, which pass through the galvanized steel pipes in the concrete, and by locking them in that way. The process of strengthening the ropes in the post-tensioning is made after pouring the concrete, not before it. It differs from other prestressed systems in this respect.